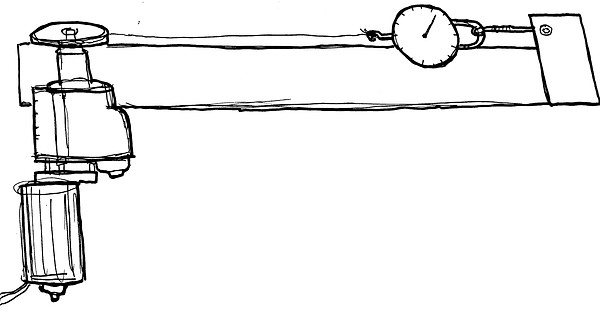

RC CVT Torque Testing Rig

🚨Note: specific details protected under NDA🚨

Role:

Design, CAD, Milling,

Fabrication

Timeline:

1 week

Tools:

Mill, 3D Printer

Context:

I was asked to find out if this RC automatic CVT (Continuously Variable Transmission) had the right stall torque and peak torque output to be used for a client’s project.

The Solution:

A testing rig made out of aluminum 80/20 and one custom aluminum plate to attach the CVT and motor. A 3D-printed wheel fixed at the transmission output attaches to a cable that tugs on a hanging scale fixed at the end of the rig.

Process:

Honestly, I had no clue what a CVT was when I got this assignment, so I was due for a bit of research. I learned that a CVT is an automatic transmission that can change seamlessly through a continuous range of gear ratios, instead of shifting in steps between a limited number of fixed gear ratios. The continuous nature of CVTs allow the engine to operate at an optimal fixed RPM while the CVT outputs an infinite range of speeds and torques. CVTs can come in a variety of forms but I have included a diagram of a pulley-based CVT to give an idea of the general concept.

Once I understood the CVT, I sketched out a design and got to building.

I repurposed some 80/20 that was lying around to make the frame, milled an aluminum plate to attach the CVT to the frame, and designed a 3D-printed wheel to go on the CVT output shaft.

All the Arduino coding and data collection was done by a fellow intern, Collin Elmer (very nice guy). He also iterated the 3D-printed wheel to perfection by adjusting the dimensions to fit perfectly on the CVT output shaft and switching over to fiber reinforced 3D printing filament so that the wheel would stop breaking when the torque got too high.

The plan was to run the RC motor at various fixed RPMs and measure the peak and stall torque at each level.

To find these torque values, we just used inputted the kilogram reading of the hanging scale and the radius of the 3D-printed wheel to the basic torque equation above (assuming theta as 90).

The rig worked beautifully, but the data revealed the CVT didn't have the right specs for the job.